A new technique has been introduced for making hydrogels, using ultrasound and avoiding harmful substances.

Using ultrasound, researchers at McGill University and Polytechnique Montréal developed a novel method of producing hydrogels that does not require hazardous chemical initiators. This innovation creates hydrogels that are stronger, more flexible, and extremely resistant to freezing and dehydration while also providing a quicker, cleaner, and more environmentally friendly method of hydrogel production. Additionally, the novel technique is expected to support advancements in 3D bioprinting, bioadhesives, and tissue engineering (1✔ ✔Trusted Source

Ultrasound unlocks a safer, greener way to make hydrogels

Go to source

).

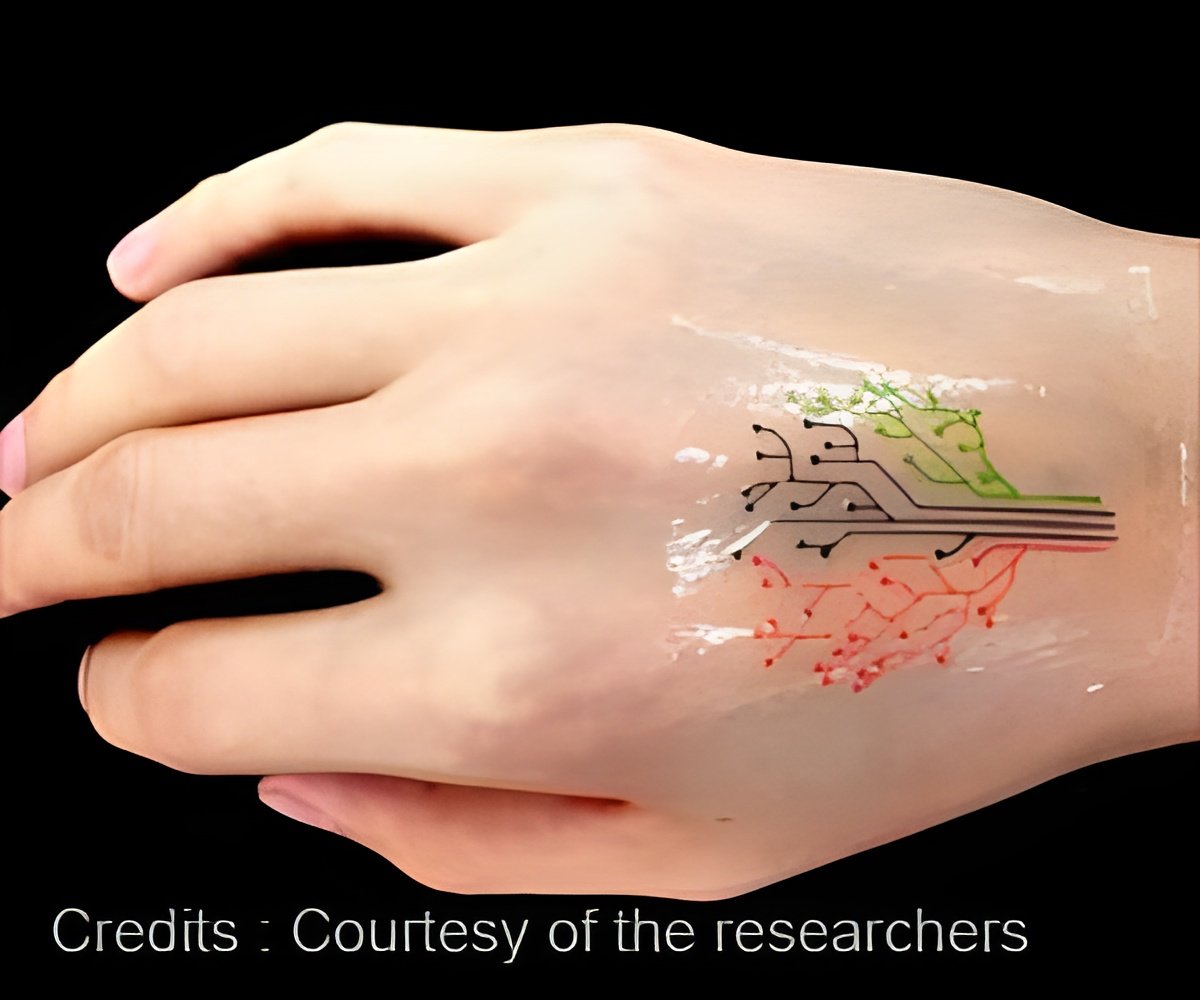

Hydrogels are gels made of polymers that have a high water absorption and retention capacity. Wound dressings, drug delivery, tissue engineering, soft robotics, soft contact lenses, and other fields all make extensive use of them.

Gel development in a matter of minutes

Conventional hydrogel production uses chemical initiators, some of which are hazardous, especially when used in medical settings. Chemicals known as initiators are employed to start chemical chain reactions. Under the direction of Jianyu Li, a professor of mechanical engineering, the McGill research team has created an alternate technique that makes use of ultrasound. Sound waves produce tiny bubbles that burst with tremendous energy when applied to a liquid precursor, causing gel to form in a matter of minutes.

“The dependence on hazardous chemical initiators was the issue we sought to address,” Li stated. “By removing these substances, our method improves the process for both the environment and human health.”

The term “sonogel” refers to this ultrasound-driven method.

“Under UV light, typical hydrogel synthesis can take hours or even overnight,” Li explained. “Ultrasound takes only five minutes to complete.”

Transforming biomedical applications

The use of this technology in non-invasive medical procedures is among its most promising applications. Due to the profound tissue penetration of ultrasonic waves, this technique may allow for the production of hydrogel inside the body without the need for surgery.

Imagine using ultrasound to precisely harden a liquid precursor that has been injected, Li explained. “This has the potential to revolutionise regenerative medicine and the treatment of tissue injury. With more improvement, we can open up new avenues for the creation of safer, more environmentally friendly materials.

Additionally, the method makes 3D bioprinting based on ultrasound possible. Researchers could precisely “print” hydrogel structures using sound waves rather than heat or light.

“We can shape and construct hydrogels with amazing accuracy by utilising high-intensity focused ultrasound,” stated Jean Provost, an assistant professor of engineering physics at Polytechnique Montréal and one of the study’s co-authors.

Reference:

- Ultrasound unlocks a safer, greener way to make hydrogels – (https://www.sciencedaily.com/releases/2025/05/250509132214.htm)

Source-McGill University

Leave a Reply